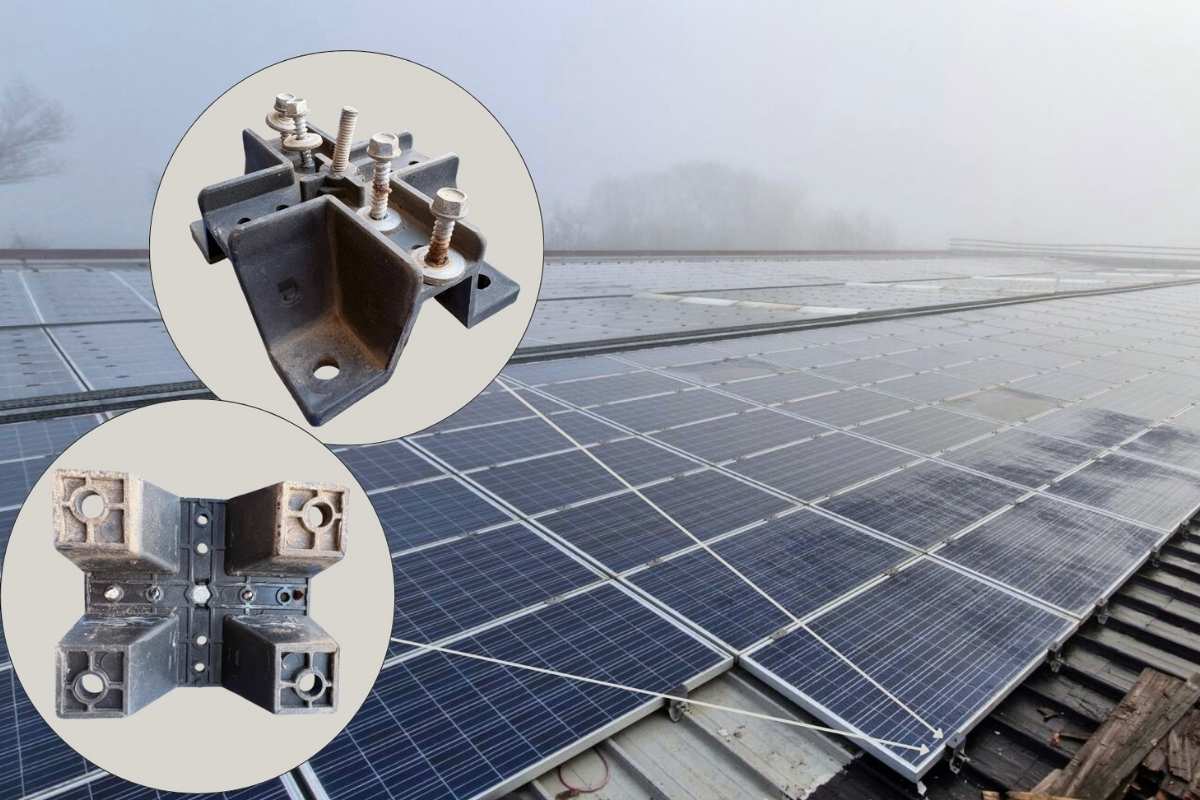

In the photovoltaic sector, the choice of mounting systems for photovoltaic panels is a strategic decision that can determine the efficiency, safety and long-term durability of a system. As it is worth remembering, looking to the future means making conscious choices today, based on products that guarantee proven reliability in real-world conditions.

This article presents all the types of mounting systems offered by our company, from systems for corrugated metal sheets and sandwich panels, to solutions for residential roofs, flat roofs and ground-mounted installations.

A concrete example is also shared: the photovoltaic system installed on the roof of the Nexus warehouse 15 years ago, which continues to demonstrate the strength and reliability of the mounting systems over time. This is clear evidence of how the choice of mounting systems directly affects the stability of a photovoltaic installation, the maintenance required over the years and its overall performance. Choosing solutions designed to last reduces the risk of deterioration and unexpected costs, ensuring a safer return on investment.

All Nexus Srl mounting system types

Nexus Srl offers a complete range of photovoltaic panel supports and photovoltaic mounting systems, designed to adapt to any surface and inclination. Since 2009, the company has stood out for innovation, versatility and certified quality.

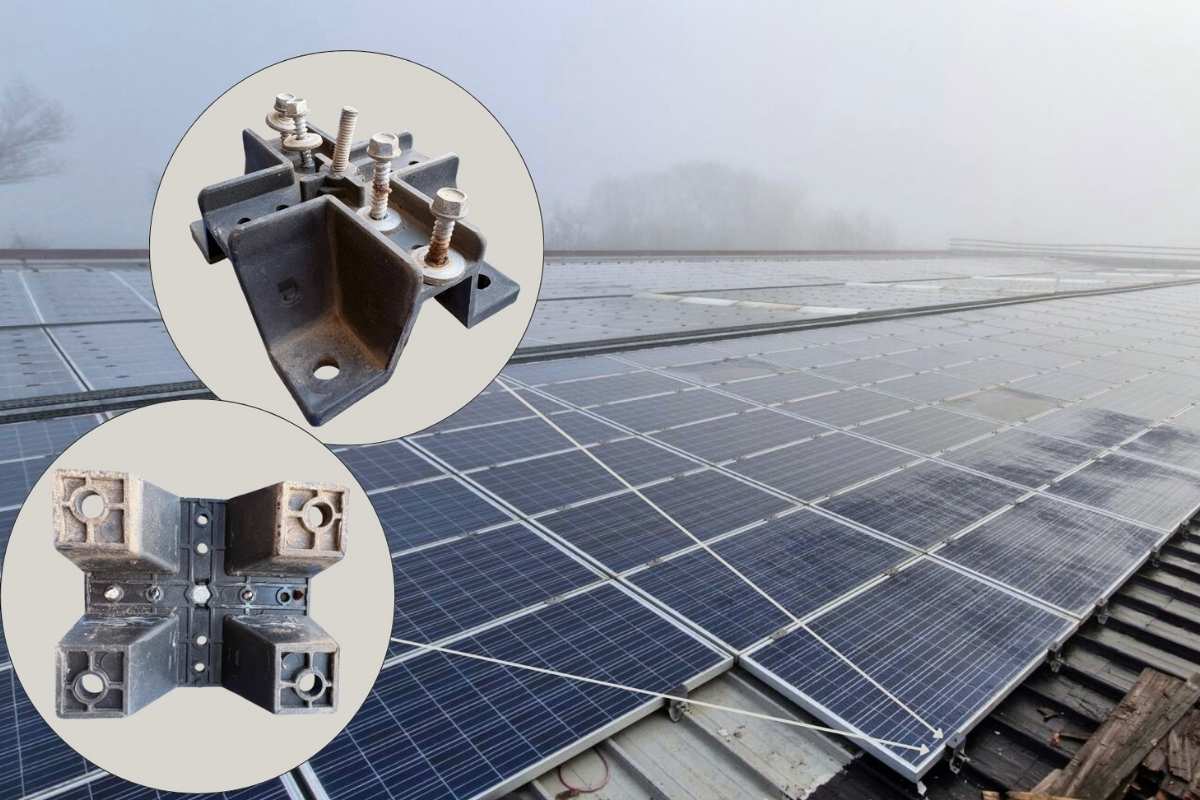

Corrugated metal sheets and sandwich panels: A, B and C brackets adapt to six different corrugation profiles, while D and E brackets and the universal Profile are fixed on the upper part of the corrugation. This ensures a safe, durable and universally compatible photovoltaic mounting solution for industrial roofs.

Tiled roofs: the G bracket allows installation on residential roofs, both on reinforced concrete slabs and wooden decking, offering an integrated photovoltaic mounting system that adapts to the roof structure without compromising aesthetics.

Ground-mounted systems: the lightweight plastic ballast can be filled on site with water or sand, simplifying transport and installation. This solution makes panel mounting easy even for ground-mounted systems, ensuring stability and safety.

Flat roofs: thanks to the tilt system or the ballast for flat roofs, panels can be positioned following the surface profile and making the most of the available space. In this way, flat roof photovoltaic mounting optimises panel exposure and overall energy performance.

These systems guarantee versatility, universal compatibility and ease of installation, without compromising safety or the energy efficiency of the photovoltaic system.

Advantages of Nexus mounting systems

Choosing Nexus mounting systems means investing in certified quality, reliability and practicality.

- Certified safety and quality: tests carried out in accredited laboratories ensure high standards for every photovoltaic panel anchoring system.

- Durable and eco-friendly materials: glass-fibre-reinforced nylon, also available in V0 flame-retardant class.

- Quick and easy installation: lightweight components that are easy to transport reduce installation times.

- Energy efficiency: the design reduces panel overheating, improving the overall performance of the system.

- Versatility: suitable for industrial and residential roofs, flat roofs and ground-mounted systems, including integrated photovoltaic mounting solutions.

- Cost savings: for the same installed power, they are more cost-effective than traditional aluminium systems.

- Refined aesthetics: panel positioning follows the profile of the supporting surface.

These advantages make Nexus systems strategic and safe choices, suitable for photovoltaic installations of any size.

From the Nexus roof, 15 years of reliability

The photovoltaic system installed on the roof of the Nexus Srl warehouse 15 years ago, using the plastic A bracket, represents a clear and emblematic case.

During a revamping intervention, technicians assessed the condition of the mounting systems exposed to sun, wind and rain. The result: the brackets are perfectly intact, with no signs of failure or structural degradation.

Comparison with other components highlights the product quality: while the screws show normal signs of wear, the brackets retain their mechanical and functional characteristics unchanged.

For this reason, Nexus Srl recommends relying on mounting solutions designed to last over the long term. High-quality choices reduce extraordinary maintenance, unexpected costs and unplanned interventions.