Plastic Pool Grates? A choice of design too

When talking about pools, attention is often focused exclusively on the size, development, and elements to be considered for water cleaning and filtration. Less attention is given to plastic grids, despite being a fundamental component for both safety, water drainage, and the aesthetics of the surrounding area. Therefore, it is important to better understand the significance of pool grids by identifying their main characteristics and the reasons why plastic is preferred over other materials.

- What are pool grids and what are they for

- The advantages of plastic grids

- The added value of the aesthetics of plastic pool grids

- Pool grids by NEXUS

What are pool grids and what are they for

Originally designed with a primarily practical purpose, plastic grids have now become a real design opportunity capable of enhancing the entire environment. From a functional standpoint, the grids are intended to ensure proper water drainage to avoid dangerous stagnation. The plastic grid is designed to promote rapid water flow, thus reducing the risk of accumulation and improving the safety of the poolside pavement. Furthermore, the plastic grid must ensure adequate resistance to various elements: from chlorine and chemicals used for pool and water treatment, to UV rays and weather conditions for outdoor pools. The surface of the plastic pool grids must also be carefully designed to provide sufficient grip, reducing the risk of accidental slips.

The advantages of plastic grids

Why choose a plastic grid instead of one made from another material? Alternatives typically include grids made from PVC, reconstituted stone, or stainless steel. Although each option has advantageous characteristics, plastic grids are preferred because they combine the best benefits. We are talking about a material that ensures extraordinary resistance to weather agents and chemicals, thus avoiding deterioration or corrosion. It should also be considered that plastic is an extremely lightweight, flexible, and versatile material that facilitates both design and installation (as well as maintenance). There is also the issue of safety. The non-slip surface and absence of sharp edges make plastic grids more suitable for use around a pool. Not to mention how comfortable they feel when in contact with bare feet.

These advantages translate not only into greater safety but also into significant long-term cost savings. Finally, technological advancements in the plastics industry have allowed for the development of aesthetically pleasing solutions. Today, plastic pool grids are available in various colors and finishes, making them easy to integrate into any architectural style.

The added value of the aesthetics of plastic pool grids

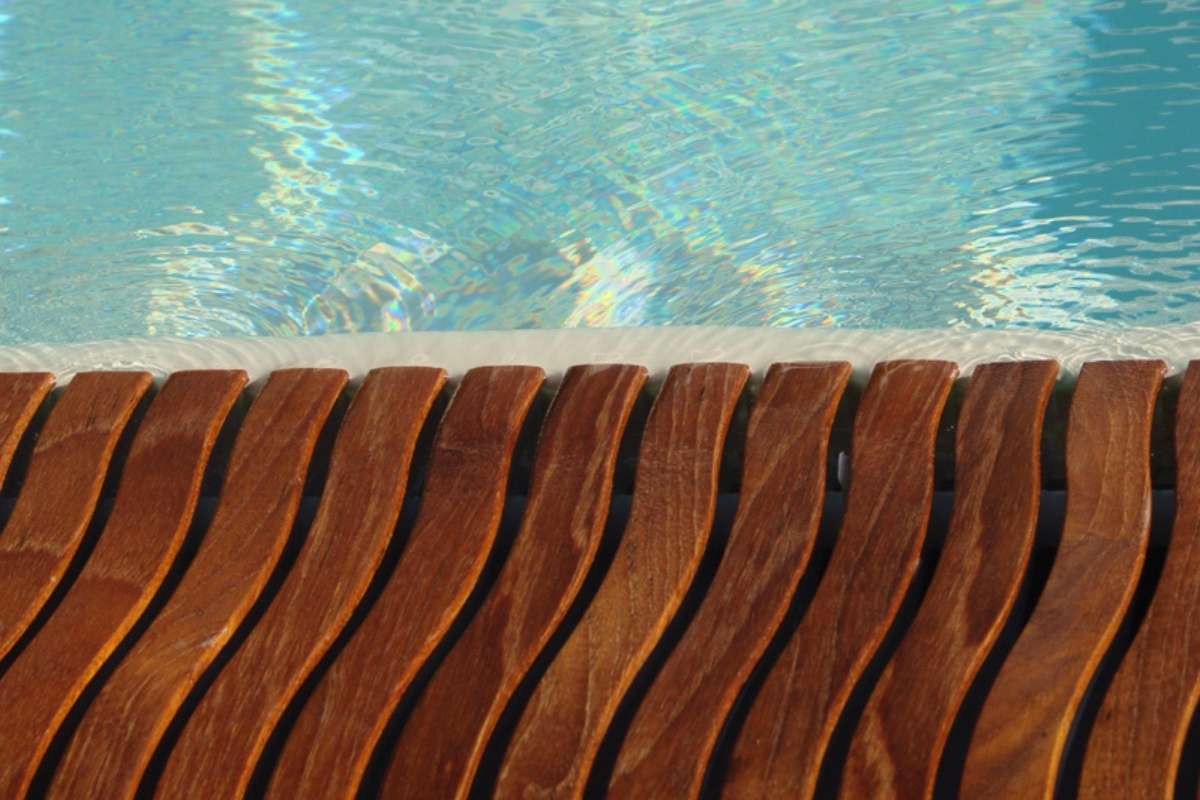

It is important to overcome the prejudice that plastic is a low-quality material incapable of enhancing a component’s aesthetics. Modern plastic grids are a beautiful example, offering innovative aesthetic solutions that enhance the pool and its surroundings. This is possible mainly due to the wide range of colors available. Plastic grids are no longer made in neutral colors like white or gray; instead, they come in a broad spectrum of shades. From wood-effect brown to beige, to customizable colors that replicate brand color schemes or create striking contrasts with the surrounding space. Beyond the purely chromatic aspect, it should be noted that plastic grids today can be made not only with smooth finishes but also with rough (embossed) textures and unique designs. This is made possible by innovations in manufacturing technologies that allow each grid to become a truly unique component.

This uniqueness is also evident in the shapes and configurations available: linear, curved, or angular models that adapt to any pool perimeter, including curved ones or those with special shapes. It’s important to remember that plastic grids are not only used around pool edges, but can also be employed in other contexts. From poolside and drainage channels in both public and private pools to wellness centers, spas, solariums, yachts, and water parks, as well as hospitality structures.

Pool grids by NEXUS

Speaking of innovation, it’s interesting to highlight the advantages made possible by bi-material molding technology. This is a process that allows polypropylene (a very versatile thermoplastic material known for its resistance to chemicals, corrosion, and wear) to be combined with other materials such as wood or rubber, with the added benefit of not requiring adhesives. Bi-material molding ensures a perfect bond between the two elements, resulting in a product that is as light and durable as plastic, but also more appealing and comfortable like wood or another natural material. The combination of two materials, as seen in the pool grids designed and manufactured by NEXUS, also enhances the safety of these components by increasing their non-slip properties. Moreover, the absence of adhesives reduces the risk of grid deterioration typically caused by moisture and the action of chemicals present in water, extending the longevity of the component. This solution represents the perfect balance between functionality, safety, and aesthetics, contributing to making the pool environment even more welcoming and refined.