Custom Plastic Molding with Nexus

The plastic molding sector is one of the cornerstones of modern manufacturing, enabling the creation of custom components for a wide range of applications. Nexus offers its customers a cutting-edge service that starts from an idea and leads to the concrete realization of the finished product. Thanks to its extensive expertise and the use of advanced technologies, the company can transform any concept into a tangible object, perfectly functional and optimized for industrial production.

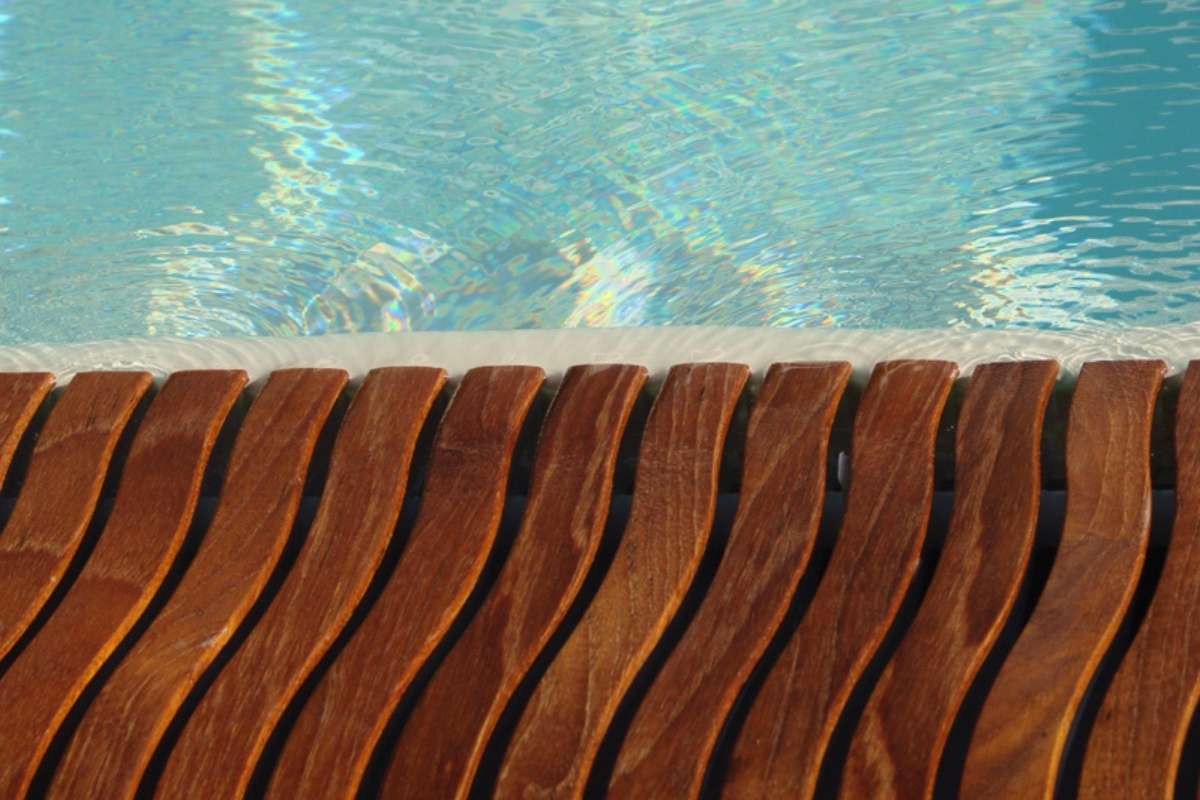

In addition to its pool grates, solar panel mounting systems, water recovery solutions, and construction products, Nexus also provides the opportunity to develop custom plastic molds, designed to precisely meet each client's specific needs. Every stage of the process, from design to mold creation, is carefully planned to ensure the highest product quality while optimizing production costs and timelines. With its vast experience, the company excels in various plastic molding processes, offering high-performance and innovative plastic molding solutions for multiple sectors, including automotive, construction, household appliances, and furniture.

From Idea to Mold: A Tailor-Made Process

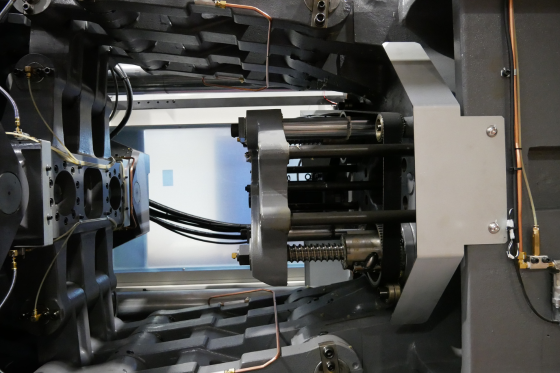

One of Nexus’s key strengths is its ability to provide a comprehensive plastic molding service, from design to mold production. Clients can present their ideas, which are then analyzed and transformed into a prototype using the latest design technologies. The plastic molds are manufactured with high-quality materials and innovative techniques, such as gas-assisted molding and MICROCELL technology, ensuring maximum precision and long-lasting durability.

The company operates a state-of-the-art machine park, featuring medium-to-high tonnage injection presses that run 24/7. This infrastructure allows Nexus to handle both large-scale productions and custom niche requests. Additionally, thanks to a highly automated and controlled plastic material processing system, Nexus guarantees exceptionally high-quality standards, minimizing waste and maximizing production efficiency.

Nexus in the Network

Nexus collaborates with leading industry partners to provide a comprehensive and highly specialized service. Among these, DPS - Dynamic Production System and Idea Company stand out.

- DPS specializes in the design and manufacturing of injection molds, offering advanced solutions for the plastic molding industry.

- Idea Company takes an innovative approach to engineering and industrial design, developing new products and optimizing existing processes.

This synergy enables Nexus to offer an integrated service, from design to production, with an unmatched level of quality and innovation.

Advanced Technology and Application Sectors

The wide range of technologies used by Nexus allows the company to meet the needs of various industrial sectors. It serves industries such as automotive, household appliances, construction, and many more, requiring high-precision plastic components. By utilizing solutions like gas-assisted molding and bi-material molding, Nexus delivers technically advanced products with outstanding aesthetic results.

The company’s injection presses cover a broad range of tonnages, allowing the processing of advanced engineering polymers. Additionally, continuous research into innovative solutions enables Nexus to stay ahead of market demands, offering stronger, lighter, and more eco-friendly plastic materials.

Why Choose Nexus for Your Custom Molding?

Choosing Nexus means partnering with an expert in plastic molding, capable of delivering innovative and highly customized solutions. The company’s strengths include:

- Advanced Design – Each mold is tailored using 3D modeling and advanced simulations.

- High-Quality Materials – Carefully selected raw materials ensure durability, strength, and optimal performance.

- Efficient Production – Cutting-edge machinery, automated processes, and highly skilled personnel.

- Production Flexibility – The ability to handle both small and large-scale productions, adapting to market demands.

- Technological Innovation – The use of state-of-the-art technologies like gas-assisted molding and bi-material/bicolor solutions.

- Extreme Customization – Each product is made to measure, ensuring it meets the client's exact specifications.

- Certified Quality – The company operates under strict quality standards, guaranteeing safety and reliability in every production.

Contact Us to Bring Your Project to Life

If you have an idea and want to turn it into a finished product, Nexus is the right partner for you. With years of experience and the ability to manage every stage of the production process, the company provides a custom plastic molding service that ensures exceptional quality, precision, and competitiveness.

Contact us today for a personalized consultation and discover how we can help you bring your project to life with maximum efficiency and professionalism.